When it comes to selecting the ideal single-ply membrane for your roofing needs, two prominent contenders stand out: TPO (thermoplastic polyolefin) and EPDM (ethylene propylene diene monomer). These roofing options offer distinct qualities catering to different preferences and requirements. In this comprehensive comparison, we’ll delve into the unique attributes of TPO roofing vs. EPDM roofing, helping you make an informed decision that aligns perfectly with your roofing project.

Exploring TPO Roofing

TPO has made a significant mark in the roofing industry due to its remarkable attributes. This single-ply roofing material is celebrated for its impressive blend of durability, energy efficiency, and cost-effectiveness. Crafted from a fusion of synthetic materials, usually a combination of polypropylene and ethylene-propylene rubber, TPO roofing systems boast added strength through reinforcement with a fabric scrim. One of its standout features is its capacity to reflect sunlight and heat, making it particularly well-suited for regions with warmer climates.

TPO roofing systems are installed as a single layer on both commercial and residential roofs. They offer a range of benefits, including energy savings, flexibility, and resistance to diverse weather conditions. The installation process is relatively straightforward, but it’s important to be aware of potential variations in quality among manufacturers and the susceptibility to heat-related challenges. These considerations play a pivotal role in determining whether TPO roofing is the right fit for your roofing project.

Curious about the costs? Discover more about TPO roofing expenses and factors that influence pricing: How Much Does TPO Roofing Really Cost? Find Out Here!

〰 Advantages of TPO Roofs

- TPO roofs have excellent UV resistance, effectively reflecting sunlight and helping to keep your building cooler.

- TPO is highly resistant to punctures, tears, and impacts, which contributes to a longer lifespan for your roof.

- TPO is environmentally friendly and can be recycled, making it a sustainable choice.

〰 Disadvantages of TPO Roofs

- The long-term durability of TPO is still being proven, as it’s a relatively newer material compared to other options. Quality variations among manufacturers can lead to unpredictable lifespans, with some TPO roofs showing signs of deterioration within a decade.

- TPO membranes can be susceptible to heat-related issues. Excessive heat may cause seam separation and even cracking of the top layer, which could compromise the roof’s integrity.

- While generally resistant to chemicals, TPO roofing systems can be negatively affected by exposure to certain substances over time. Solvents, oils, and abrasive chemicals may lead to material degradation and reduce the roof’s performance.

Exploring EPDM Roofing

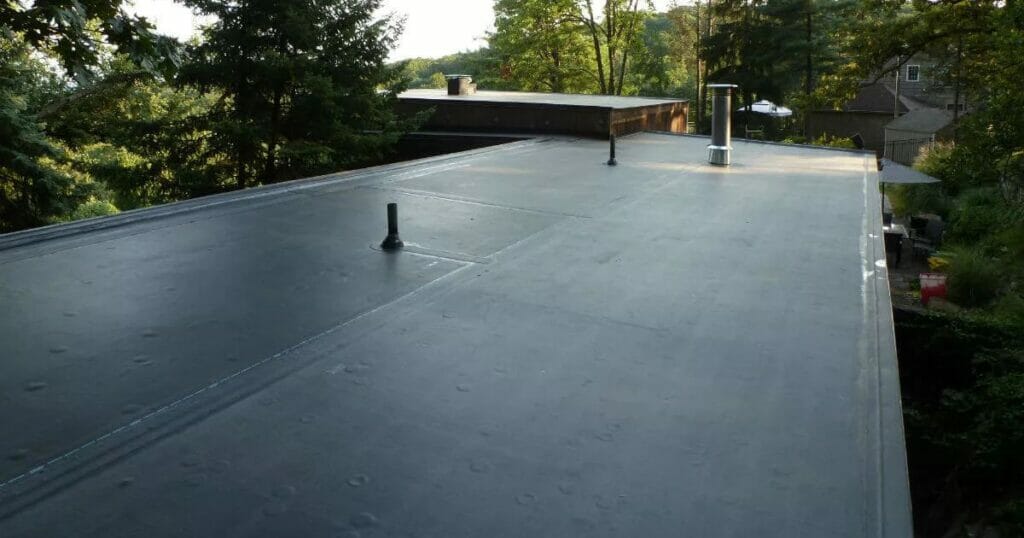

EPDM is a type of synthetic rubber roofing material widely used in both commercial and residential applications. EPDM roofing systems are known for its durability, weather resistance, and flexibility. It is commonly used for flat or low-slope roofs.

EPDM is typically available in large sheets or membranes, which can be mechanically attached, fully adhered, or ballasted to the roof structure. The material itself is composed of a synthetic rubber compound that exhibits excellent resistance to UV rays, ozone, and extreme weather conditions. This makes EPDM a reliable choice for various climates and environments.

〰 Advantages of EPDM Roofing

- EPDM roofing systems excel in challenging weather conditions, demonstrating superior resistance to hail, wind, and thermal shock.

- The flexibility of EPDM allows it to accommodate building movements without compromising the roof’s structural integrity.

- EPDM roofs are relatively low-maintenance, requiring minimal upkeep throughout their lifespan.

〰 Disadvantages of EPDM Roofing

- While EPDM roofs are generally durable, they can become more susceptible to sudden damage as they age. Hail, wind-driven debris, foot traffic, and rooftop equipment can cause punctures and other forms of damage to the membrane.

- Over time, EPDM membranes may experience shrinkage, leading to bridging and separation around vulnerable roof areas like walls, seams, and penetrations. Proper installation and design considerations are crucial to minimizing shrinkage-related issues.

- EPDM roofs can accumulate dirt, dust, and contaminants over time, potentially affecting their appearance. Regular cleaning and maintenance play a pivotal role in mitigating this issue and preserving the aesthetic appeal of the roofing system.

👉 Comparing TPO and EPDM Roofing Systems

When it comes to TPO vs. EPDM, a thorough evaluation is essential to determine the right fit for your roofing needs. Let’s delve into the key aspects that distinguish these two single-ply membrane options.

1. Durability and Longevity

TPO Roofs:

Offers impressive resistance to punctures, tears, and impacts, contributing to an extended roof lifespan. Especially suited for regions with moderate temperature fluctuations.

EPDM Roofs:

Excel in challenging weather conditions, including resistance to hail, wind, and thermal shock. Ideal for areas with extreme climate variations.

2. Installation Process

TPO Roofs:

Can be installed using various methods such as mechanical fastening, or full adhesion. Offers versatility in installation based on building structure and requirements.

If you’re considering TPO roofing for your project, don’t miss our comprehensive guide to ensure a smooth and successful installation process: Top Steps to Prepare Your Roof for TPO Roofing Installation

EPDM Roofs:

Typically installed through full adhesion or mechanical attachment. The choice of method depends on factors like the building’s design and budget considerations.

3. Energy Efficiency

TPO Roofs:

Boast reflective properties that enhance energy efficiency by reflecting sunlight. This reflective quality can potentially lead to reduced cooling costs for the building.

EPDM Roofs:

While less reflective than TPO, EPDM roofs still offer insulation benefits. The decision regarding energy efficiency might depend on your specific goals.

Continuing on, here’s a comparison of TPO and EPDM roofing in terms of climate, budget, building design, and long-term maintenance:

4. Climate:

TPO:

Suitable for areas with varying weather patterns due to its resistance to temperature changes.

EPDM:

Excels in extreme weather conditions, offering superior resistance to hail, wind, and sub-zero temperatures.

5. Budget

TPO:

While initial costs might be higher, its longevity and minimal maintenance can lead to long-term cost savings.

EPDM:

Often more budget-friendly upfront, potentially providing cost savings at the outset.

6. Building Design:

TPO:

Comes in various colors, allowing for aesthetic customization to match different building designs.

EPDM:

Dark color might not suit all building designs, requiring consideration of aesthetic preferences.

7. Long-Term Maintenance

TPO:

Welded seams create a monolithic surface, reducing potential leakage points and making maintenance relatively easier.

EPDM:

Requires vigilant inspection of seams, but when properly cared for, can provide reliable performance over time.

👉 Making the Decision: TPO or EPDM?

The decision between a TPO and EPDM roofing system hinges on several factors, including geographical location, climate, budget, and project-specific requirements. Here are some general considerations to steer your decision:

TPO: Ideal for buildings situated in warmer climates, thanks to its energy efficiency and reflective qualities. While it offers cost-effectiveness and durability, it ensures diligent attention to seam integrity and potential quality discrepancies.

EPDM: A reliable, time-tested option suitable for diverse climates. EPDM roofs excel in longevity, ease of installation, and minimal maintenance needs. Particularly advantageous for projects constrained by budget and those seeking sustainable roofing solutions.

Consulting with roofing professionals and thoroughly assessing cost, longevity, maintenance, installation, durability, and energy efficiency factors will empower you to make a well-informed choice aligned with your project goals.

Table Comparison Between TPO and EPDM Roofing Systems:-

| Factors Considered | TPO Roofing | EPDM Roofing |

| Historical Usage | Widely adopted in modern roofing due to its versatility and newer introduction to the market | A long history of reliable performance, trusted by roofing professionals |

| Sunlight Resistance | Good resistance to UV rays, minimizing heat absorption | Moderate UV resistance |

| Attachment Methods | Often fully adhered or mechanically attached | Multiple installation options: mechanically fastened, adhered, and ballasted |

| Fusion Properties | Welded seams for the monolithic surface | Seams require careful inspection and maintenance |

Color Options | Comes in various colors, customizable to a building’s aesthetics | Typically dark-colored, may not offer as much aesthetic appeal or opportunity to customize |

| Material Cost | Slightly higher initial cost | Cost-effective choice upfront |

| Labor Cost | Labor may be slightly higher for proper installation and seam care | Generally requires less labor due to efficient installation methods |

Conclusion

In the ever-evolving world of commercial roofing, the decision between a TPO or EPDM membrane remains a pivotal one. Both options offer unique advantages and considerations that cater to varying needs and preferences. If you’re ready to select the ideal roofing material for your commercial building, consider our comprehensive comparison. By carefully evaluating the distinct features of each roofing system, you can make a confident choice that guarantees a resilient, energy-efficient, and cost-effective roofing solution.

At OConnor Contracting, we understand the significance of making the right roofing choice. Our commitment to excellence drives us to provide you with the most accurate and up-to-date information, enabling you to make an informed decision that aligns with your property’s requirements. Feel free to reach out to us at (716) 600-7663.