Complete Guide to Metal Roofing Panel Types for Your Home or Business

Metal roofs have experienced remarkable growth in popularity among homeowners and business owners wanting durable, energy-efficient roofing solutions. This surge stems from metal’s exceptional longevity, superior weather resistance, and impressive energy savings compared to traditional roofing materials. However, the success of any metal roofing project depends heavily on selecting the appropriate panel type for your architectural and functional needs.

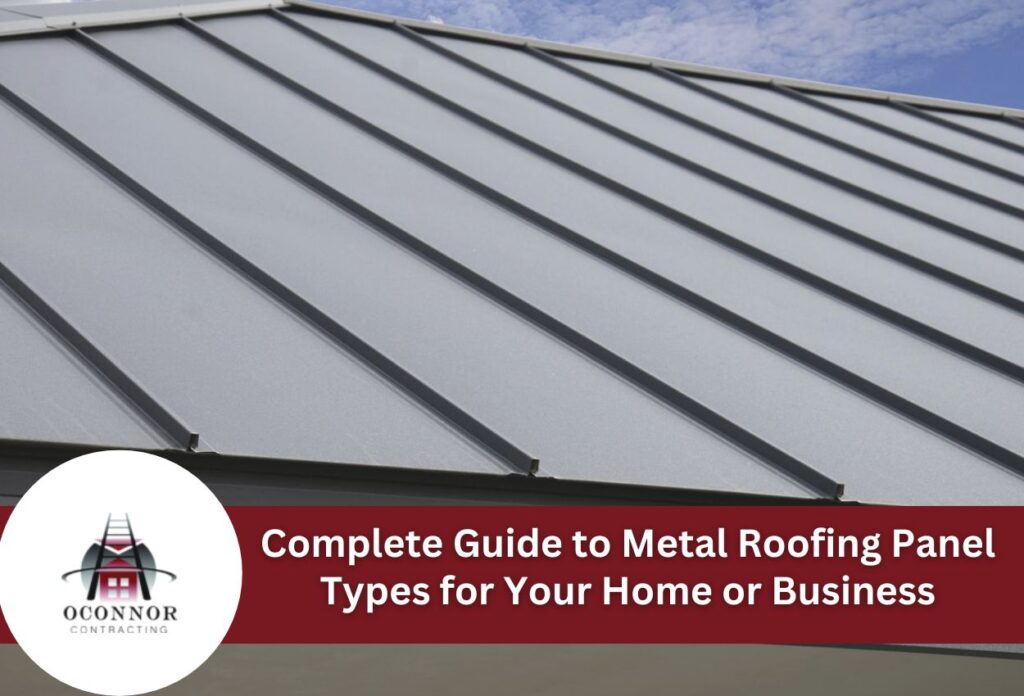

Metal roofing panel types vary in design, performance, and suitable applications. Standing seam metal roofs offer sleek, modern aesthetics with concealed fasteners, making them ideal for contemporary residential and commercial buildings. Corrugated metal panels provide cost-effective solutions with proven durability for agricultural and industrial structures. Ribbed metal roofing panels combine affordability with enhanced structural strength, while other metal roof profile options cater to specific architectural needs.

Understanding the distinctions between different metal roofing materials and profiles helps property owners choose an option that balances their aesthetic preferences, structural requirements, and long-term expectations. Each panel type has advantages in terms of installation complexity, maintenance requirements, and weather resistance capabilities. Your choice of metal roofing panel ultimately impacts both the look and performance of your property for decades to come.

Standing Seam Metal Roofing Systems: The Robust Option

Standing seam metal roofs represent the premium option among metal roofing panel types, distinguished by their sophisticated concealed fastener system and distinctive vertical leg design. These panels connect through raised seams that run vertically along the roof slope, creating clean, uninterrupted lines that enhance architectural appeal. The concealed fastener system eliminates visible screws or nails on the roof surface, preventing potential leak points while maintaining the sleek appearance that makes standing seam systems highly sought after for residential and commercial applications.

The vertical leg design of standing seam panels has both aesthetic and practical benefits. These raised seams typically measure between 1 and 3 inches in height, creating shadow lines that add dimension to the roof surface. The interlocking mechanism allows panels to connect seamlessly while accommodating the natural expansion and contraction that occurs with temperature fluctuations.

The performance benefits of standing seam metal roofing systems extend well beyond their attractive appearance. The concealed fastener design provides superior weather resistance by eliminating holes through the panel, significantly reducing the risk of water infiltration. These systems excel at accommodating thermal movement through floating clip systems that allow panels to expand and contract freely without stressing the fasteners. This thermal movement accommodation contributes to exceptional long-term durability, often lasting 50 years or more, with fewer maintenance needs compared to other metal roof profile options.

Corrugated Metal Panels: The Traditional Choice

Corrugated metal panels feature the traditional wave pattern that has defined metal roofs for generations, utilizing repetitive ridges and valleys to create exceptional structural strength. The corrugated profile distributes weight across multiple contact points, allowing these panels to span greater distances without additional structural support compared to flat metal sheets. This wave-pattern construction creates a natural stiffening effect that improves the panel’s resistance to wind uplift, snow, and other environmental stresses while maintaining a relatively light weight.

The structural advantages of corrugated metal panels stem from their ability to channel water efficiently while providing multiple load-bearing ridges. Each ridge acts as a structural beam, transferring loads to the supporting framework and preventing panel deflection under various weather conditions. This design principle makes corrugated panels particularly effective for applications requiring both durability and affordability.

Common applications for corrugated metal panels span residential, agricultural, and commercial settings where cost-effectiveness is a primary consideration. Agricultural buildings such as barns, equipment storage facilities, and livestock shelters frequently utilize corrugated panels due to their proven durability and straightforward installation. Commercial warehouses, manufacturing facilities, and industrial buildings benefit from the rapid installation and long-term performance of corrugated systems. Residential applications include accent walls, porch roofs, and utility buildings where the distinctive corrugated appearance complements rustic or industrial architectural styles while delivering reliable weather protection.

Ribbed Metal Roofing Panels for a Classic Look

Ribbed metal roofing panels include a diverse range of options that bridge the gap between flat metal sheets and deeply corrugated profiles. These metal roof profile options feature varying rib heights and spacing patterns that directly influence their structural performance and design. Minor ribs typically measure between 1/4 and 1 inch in height, providing subtle texture and moderate structural enhancement while maintaining a relatively low profile appearance. Major structural ribs can extend over 1 inch in height, creating pronounced shadow lines and delivering significantly increased load-bearing capacity.

The spacing patterns of ribbed metal roofing panels vary based on intended applications and performance requirements. Closely spaced ribs create more support points that distribute weight more evenly across the panel surface, while wider rib spacing produces more dramatic visual effects with deeper shadow lines. These geometric variations allow architects and contractors to select ribbed metal roofing panels that complement specific architectural styles while meeting structural performance criteria.

The ribbed panel design significantly affects drainage through the defined flow channels that direct water toward gutters and downspouts. The raised ribs act as barriers that prevent lateral water movement, while the valleys between ribs form drainage pathways. This controlled drainage pattern reduces the likelihood of standing water and ice dams during freeze-thaw cycles. Snow load capacity increases substantially with rib height and frequency, as the raised profiles create structural support that prevents panel deflection under heavy snow. The enhanced structural integrity provided by the ribbed design makes these metal roofing panel types suitable for regions where severe weather is common, while offering design flexibility for various applications.

Metal Roofing Profile Options and Architectural Styles

Metal roofing profiles significantly influence the visual impact and architectural compatibility of different building types. Low-profile panel designs maintain subtle elevations typically ranging from 1/2 inch to 1 1/2 inches, creating understated appearances that complement contemporary residential and commercial buildings with clean, minimalist aesthetics. These profiles work well on homes with modern design elements or commercial structures where visual continuity takes precedence.

High-profile panel designs feature more pronounced elevations extending from 2 to 4 inches in height, generating bold shadow lines that enhance architectural character and depth. Traditional farmhouses, rustic residential designs, and industrial buildings benefit from these prominent profiles that create contrasts throughout different lighting conditions. The elevated profile heights also provide enhanced structural performance for buildings requiring greater load-bearing capacity or extended panel spans.

Specialty profile systems address architectural requirements through advanced connection methods and distinctive aesthetic features. Snap-lock systems utilize precision-engineered clips that allow rapid installation while maintaining weather-tight seals without exposed fasteners. Mechanical seam profiles feature machine-formed connections that create continuous weather barriers ideal for low-slope applications. Batten seam systems incorporate raised caps that cover panel connections, producing traditional styling with enhanced weather protection. These specialized metal roof profile options enable architects to specify roofing systems that meet both performance criteria and specific designs for residential and commercial projects.

Metal Roofing Material Options and Performance Characteristics

The metal material you choose also plays a crucial role in determining long-term performance, durability, and maintenance requirements. Steel remains one of the most widely used materials for metal roofs due to its exceptional strength-to-weight ratio and cost-effectiveness. Steel panels typically weigh between 1 and 3 pounds per square foot, providing durable performance without requiring additional roof framing modifications. The corrosion resistance in steel panels depends heavily on protective coatings, with properly coated steel roofing systems achieving service lives of 40 to 70 years under normal environmental conditions.

Aluminum offers superior corrosion resistance compared to steel, particularly in coastal environments where salt exposure accelerates metal deterioration. Aluminum metal roofing materials also weigh less than comparable steel panels, making them ideal for structures with limited load-bearing capacity or retrofit applications. The natural oxide layer that forms on aluminum surfaces provides corrosion protection, contributing to longevity expectations of 40 years or more with minimal maintenance requirements.

Copper represents the premium option among metal roofing materials, developing its characteristic patina over time while delivering exceptional durability spanning centuries when properly installed. Zinc roofing materials provide similar longevity and naturally weather to an attractive gray patina. Coating systems enhance the performance of base metals through multiple layers of protection. Galvanized coatings apply zinc protection directly to steel substrates, while Galvalume coatings combine aluminum and zinc for enhanced corrosion resistance. Painted coating systems add color and additional weather protection, with premium paint finishes often having 30 to 40-year warranties.

Selecting the Right Metal Panel Type for Your Project

Choosing the best metal roofing panel type for your property requires reviewing multiple factors. Climate conditions should be a primary consideration when comparing metal roofing panel types, as environmental exposure patterns determine material durability and maintenance requirements. Regions with heavy snowfall benefit from higher-profile panels like standing seam or ribbed metal roofing panels that provide enhanced structural support and efficient snow shedding. Coastal areas with salt air exposure require aluminum or premium-coated steel materials to prevent accelerated corrosion, while inland locations can utilize standard galvanized or Galvalume coating systems effectively.

Building structure capabilities influence panel selection through load-bearing capacity and span requirements. Existing structures may require lighter aluminum panels or profiles with closer support spacing, while new construction allows greater flexibility in selecting heavier steel systems or wide-span configurations. Budget parameters affect your choice of metal roofing options, with corrugated metal panels offering less expensive solutions and standing seam systems representing premium investments with enhanced longevity.

Local building codes establish minimum performance standards for wind resistance, fire ratings, and structural requirements that vary by geographic region. Professional installation is critical when evaluating different metal roof profile options, as panel complexity directly affects labor requirements and installation timelines. Corrugated metal panels typically allow faster installation with standard tools, while standing seam metal roofs require specialized equipment and experienced installers for proper seam formation and weatherproofing, ultimately influencing long-term maintenance needs and system reliability.

Explore Your Metal Roofing Options with OConnor Contracting

The right metal roofing panel types impact both the performance and curb appeal of your home or business. At OConnor Contracting, we specialize in providing top-quality metal roofing solutions tailored to meet your specific needs. Whether you’re considering the sleek lines of standing seam metal roofs or the cost-effective durability of corrugated metal panels, our expert team is here to help you look over each option.

Understanding the differences in insulation, longevity, and maintenance requirements for various metal roofing materials, including steel, aluminum, copper, and zinc, can help homeowners make a final choice. Each material has benefits, such as corrosion resistance and eco-friendliness, which we can match with your architectural style and local climate conditions.

Don’t compromise on your investment. Call us today at (716) 600-7663 to discuss your metal roofing project and ensure you choose the best panel type for lasting satisfaction and performance.