Can EPDM be used on a pitched roof? Known for its durability, affordability, and ease of installation, EPDM has been predominantly used on flat roofs due to its exceptional waterproofing properties. However, in this article, we will delve into the possibilities and considerations of using EPDM on a pitched roof. By the end, you will have a comprehensive understanding of this topic and be equipped to make an informed decision for your roofing needs.

• Is EPDM a Good Choice for Pitched Roofs?

EPDM is a popular roofing material for commercial and industrial buildings, but it is not the ideal choice for high-pitched roofs. This is because EPDM roofs are not as durable on steep slopes as they are on flatter roofs. They can stretch, warp, and wear out over time, leaving the roof deck exposed. Additionally, EPDM roofs are vulnerable to damage from severe weather conditions such as high winds, storms, hail, heavy rain, and snow. These conditions can weaken the seams of EPDM on a pitched roof and even cause it to separate from the roof deck.

The entire roofing system may not be compatible with a steep-pitch roof. EPDM roofs require a different type of underlayment, flashing, and other roofing components that are typically not designed for use on steep sloped roofs. Trying to use an EPDM membrane with incompatible underlayment and flashing may also increase the number of issues that occur.

Considering these factors, it is advisable to explore alternative roofing materials that are better suited for high-pitched roofs to ensure long-term durability and protection against harsh weather conditions.

• The Benefits of EPDM

EPDM roofing has several benefits that have contributed to it becoming a desired roofing material for residential settings. Here are some of the key advantages:

1. Affordability: EPDM presents a cost-effective roofing solution compared to materials like metal or tile.

2. Easy Installation: EPDM can be installed quickly and efficiently, resulting in reduced labor costs.

3. Flexibility: The rubberized nature of EPDM allows it to remain flexible even in low temperatures, enabling expansion and contraction without the risk of cracking.

4. Resistance to UV Radiation: EPDM exhibits excellent UV resistance, safeguarding the underlying structure from potential sun damage.

5. Low Maintenance: EPDM requires minimal maintenance, translating to more time and monetary savings for homeowners.

• Challenges of Installing EPDM on a Pitched Roof

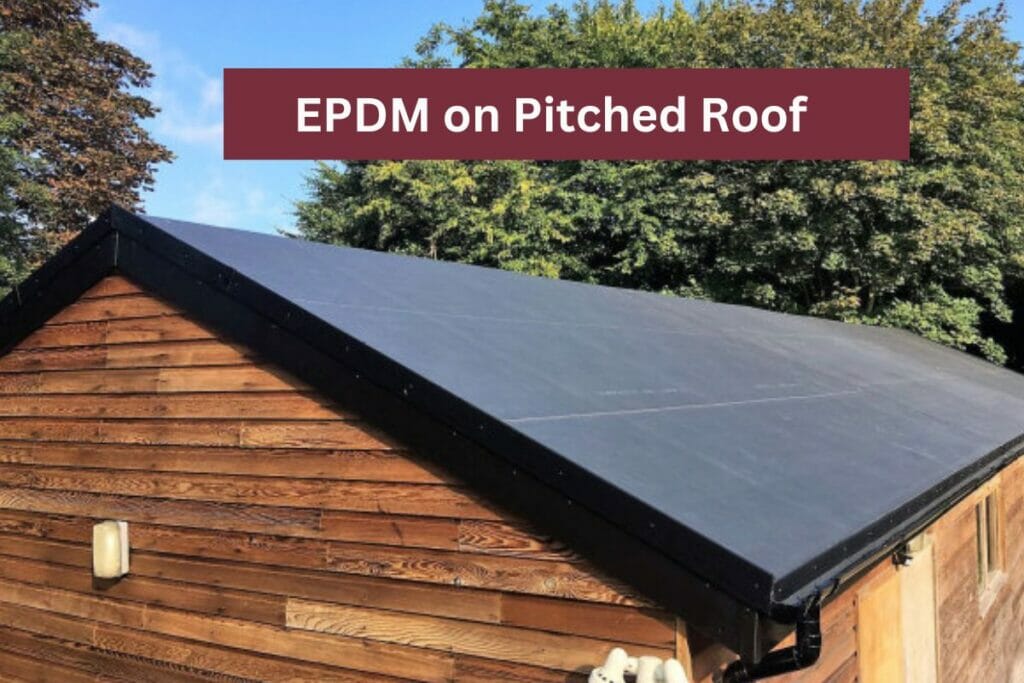

While EPDM is predominantly designed for flat roofs, it is possible to use it on a pitched roof. However, certain challenges should be acknowledged:

1. Susceptible to Damage: This type of roofing is not as durable as other options. It is more easily damaged by severe weather compared to other residential roofing materials like metal or tile.

2. Securing the Membrane: EPDM typically adheres to the roof using adhesive or fasteners. Ensuring it is properly fastened on a pitched surface can be more challenging, especially because it is typically installed in large sheets. The membrane also has numerous seams which may increase the risk of water damage.

3. Appearance: EPDM on a pitched roof may not achieve the same aesthetic appeal as other roofing materials as it comes in limited color options, mainly black.

• Considerations for Pitched Roof Applications

Before deciding to utilize EPDM on a pitched roof, it is crucial to take specific factors into consideration:

1. Pitch Angle: The angle of the roof pitch affects water runoff. EPDM is most suitable for low to moderate pitches, typically up to 6:12.

2. Climate: Evaluate the climate in your area. If you experience heavy rainfall or snowfall, alternative roofing materials might be more appropriate.

3. Roof Design: The complexity of your roof design can impact the feasibility of using EPDM. Intricate structures may pose challenges during installation and maintenance.

• Proper Installation Techniques

To ensure the successful application of EPDM on a pitched roof, it is essential to follow proper installation techniques. These may include:

1. Surface Preparation: Thoroughly clean and prepare the roof’s surface, removing any debris or contaminants that could hinder adhesion.

2. Adhesive Selection: Choose an adhesive specifically designed for EPDM installation on pitched roofs, ensuring compatibility and secure bonding.

3. Fastener Placement: Utilize appropriate fasteners strategically placed to secure the EPDM membrane effectively.

4. Seam Sealing: Pay meticulous attention to seam sealing, as water penetration can be a concern on pitched roofs.

5. Professional Installation: Consider engaging the services of a professional roofing contractor experienced in EPDM installations on pitched roofs. To delve deep into the process of EPDM installation, check our blog post on EPDM Roof Installation.

• Longevity and Durability

While EPDM is renowned for its longevity and durability, its performance on a pitched roof may vary compared to flat roofs. Factors such as the roof pitch, climate conditions, and maintenance practices will influence the overall lifespan of an EPDM roof on a pitched surface. Additionally, proper installation, routine inspections, and timely repairs will contribute to extending the lifespan of your EPDM roofing system.

If you want to know more about the longevity of an EPDM roof, check our blog post: How Long Do EPDM Roofs Last?

Final Thoughts

If you are considering using EPDM on your pitched roof, be sure to talk to one of our qualified roofing contractors at OConnor Contracting. We have years of experience installing EPDM on pitched roofs, and we can help you assess your roof’s condition and recommend the best installation method for your needs.

FAQs

A. EPDM is most suitable for low to moderate pitches. Steeply pitched roofs may not be ideal for EPDM due to water drainage and adhesion challenges.

A. EPDM is generally considered a cost-effective roofing option, but it is essential to compare costs with other materials suitable for pitched roof applications to determine the best choice for your specific needs.

A. EPDM does not typically require additional coatings for pitched roof installations. However, you can apply one if it seems necessary. Overall, it is important to ensure proper adhesion and seam sealing for effective waterproofing.