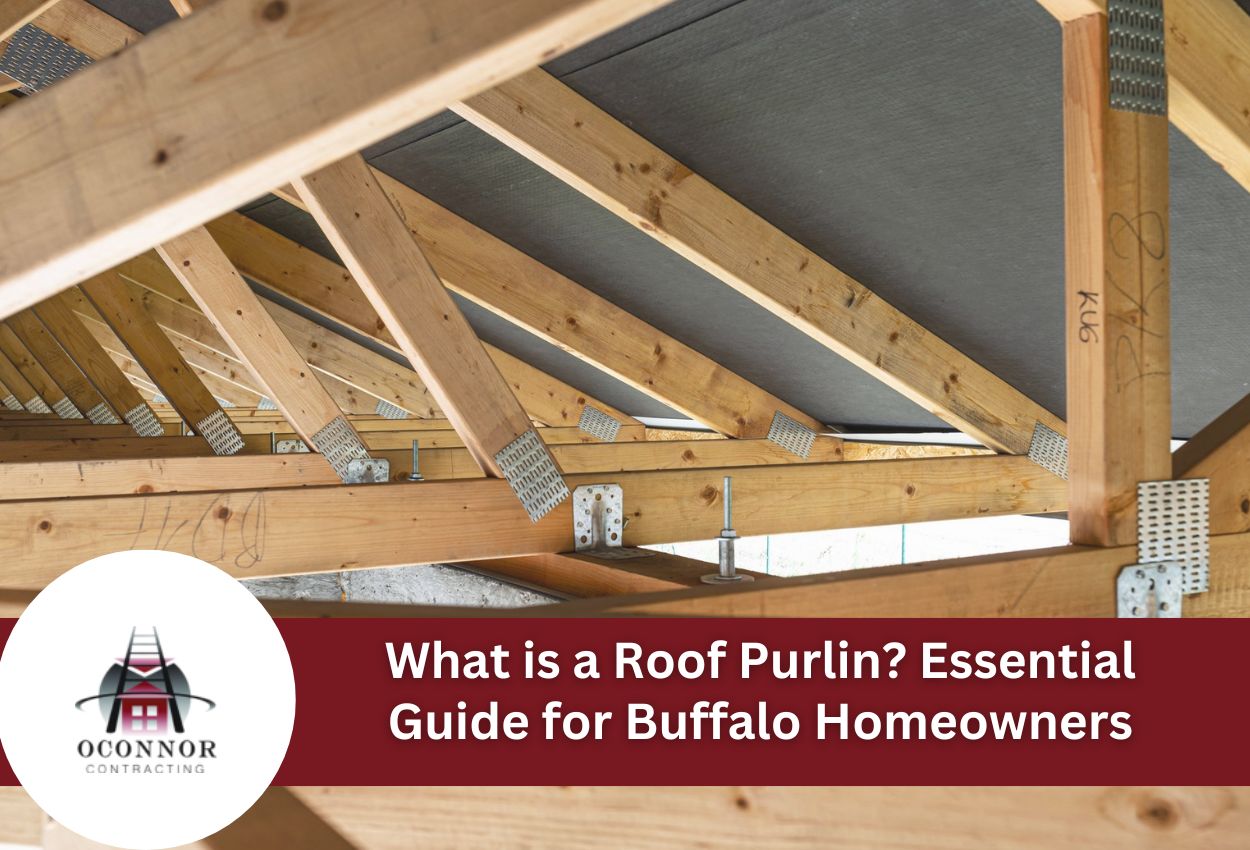

Roof purlins are horizontal structural elements that play a critical role in your home’s roofing system. These important components run perpendicular to the rafters and trusses, creating a sturdy framework that supports the roof covering. For Buffalo homeowners facing heavy snow and sometimes severe weather conditions, understanding these structural elements is particularly important. Purlins effectively transfer the weight of snow, rain, and the roofing materials themselves to the main structural frame of the building, ensuring your home remains safe and secure year-round.

Originally, purlins were simple wooden beams used in traditional construction. However, as building technology advanced, so did purlin design. Modern roof purlins are commonly made from engineered materials like steel, with specific profiles designed to maximize strength while minimizing weight. In Buffalo’s climate, where structures must withstand significant seasonal stresses, properly installed purlins provide essential support to maintain roof integrity through freezing winters and summer storms alike.

The evolution from basic wooden supports to precisely engineered metal components reflects the growing demands placed on building materials. Today’s metal roof purlins come in various configurations, with C-purlins and Z-purlins being among the most common types used in residential and commercial construction throughout Western New York. As a homeowner, it is important to understand all the parts of your roof to make the best decisions when it comes to roof maintenance and replacement options.

Types of Roof Purlins: Materials and Profiles for Different Applications

When selecting roof purlins for Buffalo properties, material choice significantly impacts performance and longevity. Steel purlins dominate the market due to their exceptional strength-to-weight ratio and ability to withstand Buffalo’s heavy snow loads. These galvanized or pre-painted steel components resist corrosion from winter salt exposure and moisture. Aluminum purlins offer excellent corrosion resistance and lighter weight, though they typically provide less structural support than steel. Traditional wooden purlins, while still used in some residential applications, require regular maintenance to prevent moisture damage in our humid summers and snowy winters.

The profile of purlins also determines their suitability for different homes. Z-purlins feature a distinctive zigzag shape, providing excellent load-bearing capacity while reducing material usage, making them ideal for commercial buildings with long spans. C-purlins, also called channel purlins, have a simple C-shaped profile that offers versatility for both residential and light commercial applications. Hat purlins, with their distinctive crown shape, provide superior support for standing seam metal roofs, which are popular in Buffalo neighborhoods.

The purlin you choose must account for roof pitch, span requirements, and anticipated loads. For Buffalo homes, where winter snow accumulation can add significant weight, professional roofers typically recommend closer purlin spacing requirements than might be standard in milder climates. The roof support structure components work as a system, with purlins forming a critical link between your roofing material and the building’s main framework.

C-Purlins vs. Z-Purlins: Making the Right Choice for Your Project

When selecting the appropriate purlin profile for your roofing project, understanding the key differences between C-purlins and Z-purlins is essential. C-purlins, named for their C-shaped cross-section, offer excellent versatility and are typically easier to install. Their symmetrical design makes them ideal for situations where purlins might need to be flipped or repositioned during installation. In Buffalo’s residential construction, C-purlins are often preferred for smaller spans and straightforward roof designs.

Z-purlins, with their zigzag profile, provide superior load-bearing capacity for the same amount of material. This makes them particularly valuable for commercial buildings with wider spans between structural supports. The Z-shape creates natural nesting capabilities when overlapped, reducing material waste during installation. For Buffalo properties with large open spaces like warehouses or commercial facilities, Z-purlins often represent the less expensive and structurally sound choice.

Buffalo’s weather considerations should factor heavily into your purlin selection. The significant snow experienced during Western New York winters requires strong structural support. Z-purlins generally offer better resistance to the downward pressure created by accumulated snow. However, in renovation projects where compatibility with existing roof support structure components is necessary, C-purlins may be preferable due to their simpler connection requirements. A professional roofing contractor can assess your specific building needs and recommend the appropriate purlin type based on your roof’s design, span requirements, and expected environmental stresses.

How Purlins Work Within Your Roof System

Understanding how purlins integrate with other roofing components is crucial for a structurally sound roof, especially in Buffalo, where extreme weather conditions test every aspect of your home. Purlins serve as the vital connection between your primary roof structure (trusses or rafters) and the roof covering itself. This creates a complete load path that transfers weight from the roof surface through the purlins and into the main structural frame of your house.

In a typical installation, purlins are secured perpendicular to rafters or trusses using specialized brackets, cleats, or direct fastening methods. These connection points are critical stress areas that must be properly engineered to prevent failure. Most metal roof purlin systems use heavy-duty bolts or self-drilling screws with weather-resistant coatings to prevent corrosion in Buffalo’s varying climate conditions. For wooden purlins, strategic notching and properly sized lag screws ensure solid attachment.

The spacing between purlins is determined by the type of roofing material, expected snow loads, and local building codes. In Buffalo, where winter snow accumulation can be substantial, purlin spacing requirements are typically more conservative than in milder regions. Professional installers carefully calculate these measurements to ensure your roof can handle the combined weight of materials, snow, ice, and wind loads. This ensures your roof performs reliably through decades of Western New York weather challenges.

Purlin Spacing and Layout: Getting the Technical Details Right

Determining the correct purlin spacing is a critical technical decision that directly impacts your roof’s structural integrity. For Buffalo homes, several key factors influence proper spacing calculations. Roof pitch plays a significant role — steeper roofs typically allow for wider purlin spacing as they shed snow more efficiently, while low-slope roofs require closer spacing to handle potential snow accumulation.

The span length between structural supports is another crucial factor. As the distance between main supports increases, purlin spacing typically needs to decrease to maintain adequate load distribution. The purlin material itself also determines appropriate spacing — steel purlins can generally span greater distances than wooden alternatives. For a typical Buffalo residential roof using metal Z-purlins, spacing often ranges from 3 to 5 feet, though this varies based on specific building requirements.

Local building codes and regulations provide guidelines for purlin layout. Buffalo’s building code incorporates snow load requirements that directly translate to purlin spacing calculations. Professional roofing contractors understand these technical requirements and can ensure your roof system meets or exceeds local standards. This technical precision is especially important in our region, where proper purlin spacing helps prevent roof collapses during heavy lake-effect snowstorms that can deposit several feet of snow within days.

Purlin Installation Best Practices for Structural Integrity

Proper purlin installation is essential for achieving maximum roof performance, especially in Buffalo, where weather conditions put additional strain on building components. While purlin installation should always be handled by professionals, it can be helpful for homeowners ot understand the process.

Begin by thoroughly preparing the site and creating a detailed layout plan that accounts for proper spacing and alignment. Measure and mark attachment points precisely on rafters or trusses before bringing purlins to the roof. When handling metal purlins, use appropriate protective gear as edges can be sharp, and avoid bending or twisting the materials, which can compromise their structural capacity.

When securing purlins, use fasteners specifically designed for your purlin type and the materials they’re connecting to. For metal purlins, galvanized or stainless-steel fasteners prevent premature corrosion. Ensure consistent torque when tightening bolts to avoid warping the purlin. Temporary bracing during installation helps maintain alignment until all connections are secure. Many installation issues stem from inadequate bracing or improper fastener selection that can lead to roof failure down the line.

Common mistakes include improper overlap at purlin joints, insufficient edge distance for fasteners, and failing to account for thermal expansion. In Buffalo’s climate, where temperatures range from below zero to over 90 degrees, allowing for this expansion is critical. Professional installers also apply appropriate sealants at connection points to prevent moisture infiltration, which is particularly important given our region’s freeze-thaw cycles that can accelerate corrosion and structural deterioration if water penetrates the roof system.

Maintenance and Problem-Solving: Keeping Your Roof Purlins in Top Condition

Regular maintenance of your roof, including purlins, is essential for Buffalo homeowners. Establishing a biannual inspection routine, ideally in spring after winter’s harsh conditions and fall before snowfall begins, can significantly extend your roof’s lifespan. During these inspections, check for visible signs of corrosion, especially at connection points where moisture tends to collect. Look for any sagging between support points, which may indicate overloading or material fatigue. After particularly heavy snowfalls, an additional inspection is recommended to ensure the purlins haven’t been compromised.

When troubleshooting purlin issues, start by examining any visible deflection or bending. Minor sagging in metal purlins might be addressed by adding supplemental supports, but significant deformation typically requires replacement. Rust and corrosion, common challenges in Buffalo’s climate, should be treated immediately. Light surface rust can often be removed and the area sealed, while advanced corrosion necessitates component replacement. Connection failures at purlin-to-rafter joints is a serious structural concern requiring immediate attention.

Know when to call a professional Buffalo roofing contractor. Any structural issues affecting purlins should be evaluated by experts, as these components are critical to your roof’s integrity. DIY repairs may compromise load-bearing capacity and void warranties or insurance coverage. Professional roofers have the equipment and expertise to safely address purlin problems while ensuring all building code requirements are met, providing peace of mind through Buffalo’s challenging seasons.

Expert Roofing Services in Buffalo with OConnor Contracting

If you’re planning a roofing project in Buffalo, understanding the role of roof purlins in your building’s structure is crucial. Choosing the right type of purlin, whether C-purlin or Z-purlin, and ensuring correct spacing and alignment are key to the longevity and safety of your roof. OConnor Contracting specializes in providing top-quality roof installation and maintenance, ensuring your roof can withstand our challenging weather conditions.

Don’t compromise on the structural integrity of your building. Ensure your roof is equipped to handle heavy snow and wind with professional installation from OConnor Contracting. Call us today at (716) 600-7663 to schedule a consultation and let our experts handle your roofing needs.